Energy Savings for the Air Force

ASHRAE Level 2 Energy Audits completed across seven bases and more than 12.3 million square feet.

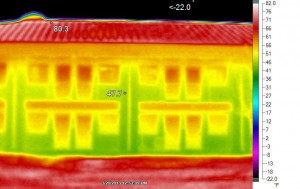

Farnsworth Group was part of an IDIQ team awarded a multi-installation contract to conduct energy infrastructure assessments throughout seven Air Force installations in the South Atlantic and Midwestern regions of the United States. These assessments consisted of facility condition inventory assessments, real property inventory, space utilization analysis, and High Performance Sustainable Building Checklist evaluation. Farnsworth Group’s tasks centered on ASHRAE Level 2 Energy Audits and project-ready energy conservation measures (ECMs).

Teams were organized to conduct field service visits over a duration of 2-3 weeks, with an intricate system of data collection and implementation of real-time data and technology use. The number of buildings Farnsworth Group assessed on each installation ranged from 14 to 205, including operational, administration, recreational, maintenance, storage, healthcare, emergency response, and dormitory buildings.

After a site visit, information collected was analyzed against current utility usage. ECMs and water saving measures (WSMs) were identified and analyzed for cost of implementation, energy savings and paybacks. All of the information was presented in a single report by installation with a prioritization of what was recommended and estimated construction cost descriptions (using RS Means).

This work involved meticulous planning, continuous and rigorous quality control, and flexibility to accommodate and be non-disruptive to ongoing Air Force mission activity. Some challenges our teams overcame included the following:

- Compressed onsite schedules required close management of multiple assessment teams for visits to hundreds of buildings in the 2- to 3-week timeframe.

- Fast-paced schedules with many moving pieces required exceptional safety oversight. Our teams operated under detailed safety and hazard mitigation plans, and we ensured adequate personal protective equipment was used by all personnel.

- Work inside facilities took place during Air Force daytime working hours. We maintained flexibility to accommodate reschedules when Air Force mission requirements prohibited or limited access.

- One-time access to each installation required that data collection had to be complete and accurate before we left the installation. A daily automated quality check of collected data was instituted to allow for next day revisits to buildings, if required.

Farnsworth Group identified numerous ECMs that would result in substantial savings, with an average simple payback on investment of four years for the total program.